The engine: Unique architecture

A real innovation

Midual was born at the end of 1992 from the founder’s idea to build a French road motorcycle fitted with a 2-cylinder engine, because in his view it is the ideal engine for a road bike, combining torque and a wide usable rev range.

Looking for a strong mechanical identity the brand investigated the flat twin engine mounted in line.

The flat twin, a 2-cylinder horizontally opposed engine, is a major power source, whether in the fields of motorcycles, automobiles or aircraft, because it uniquely combines the best natural balance (absence of vibrations) and perfect cyclic regularity (flexibility and free-revving qualities).

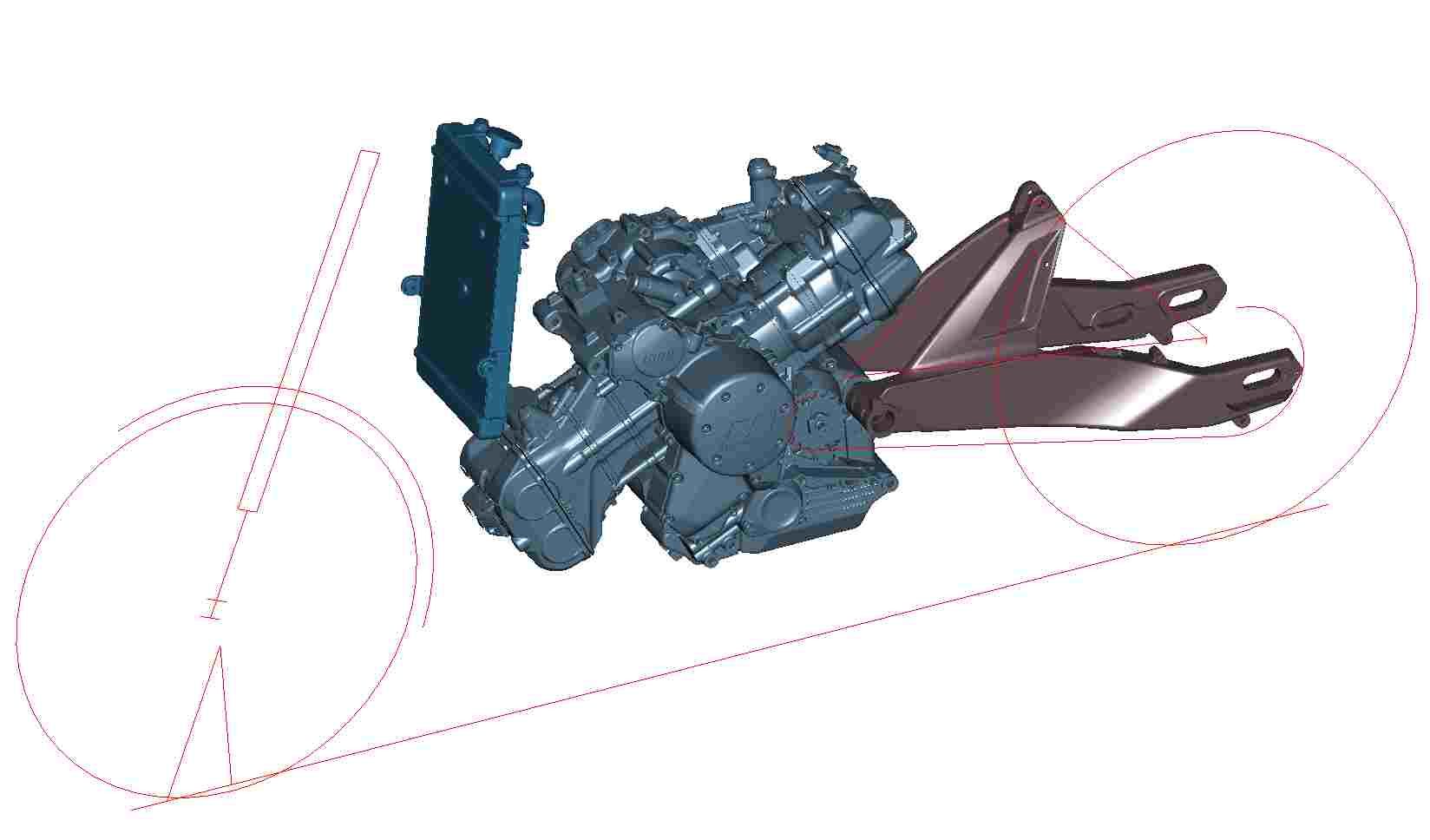

Nevertheless, this type of engine is bulky and this is why no manufacturer has fitted it lengthwise (with the crankshaft across the frame) in a motorcycle since the middle of the 1930s. Mainly because it seemed impossible to house it taking into account the constraints of construction of the chassis of a modern machine with a swinging arm rear suspension.

It is this old problem that Midual has succeeded in solving, thanks to several original ideas, the most visible of which is the mounting of the engine at an angle with the front cylinder head pointing downwards. This innovation is covered by 5 international patents.

The achievement was recognised by two engine specialists from a German manufacturer of 6-cylinder horizontally opposed engines whose comment was “you have at last placed the flat twin in the right direction ! »

Detailed description

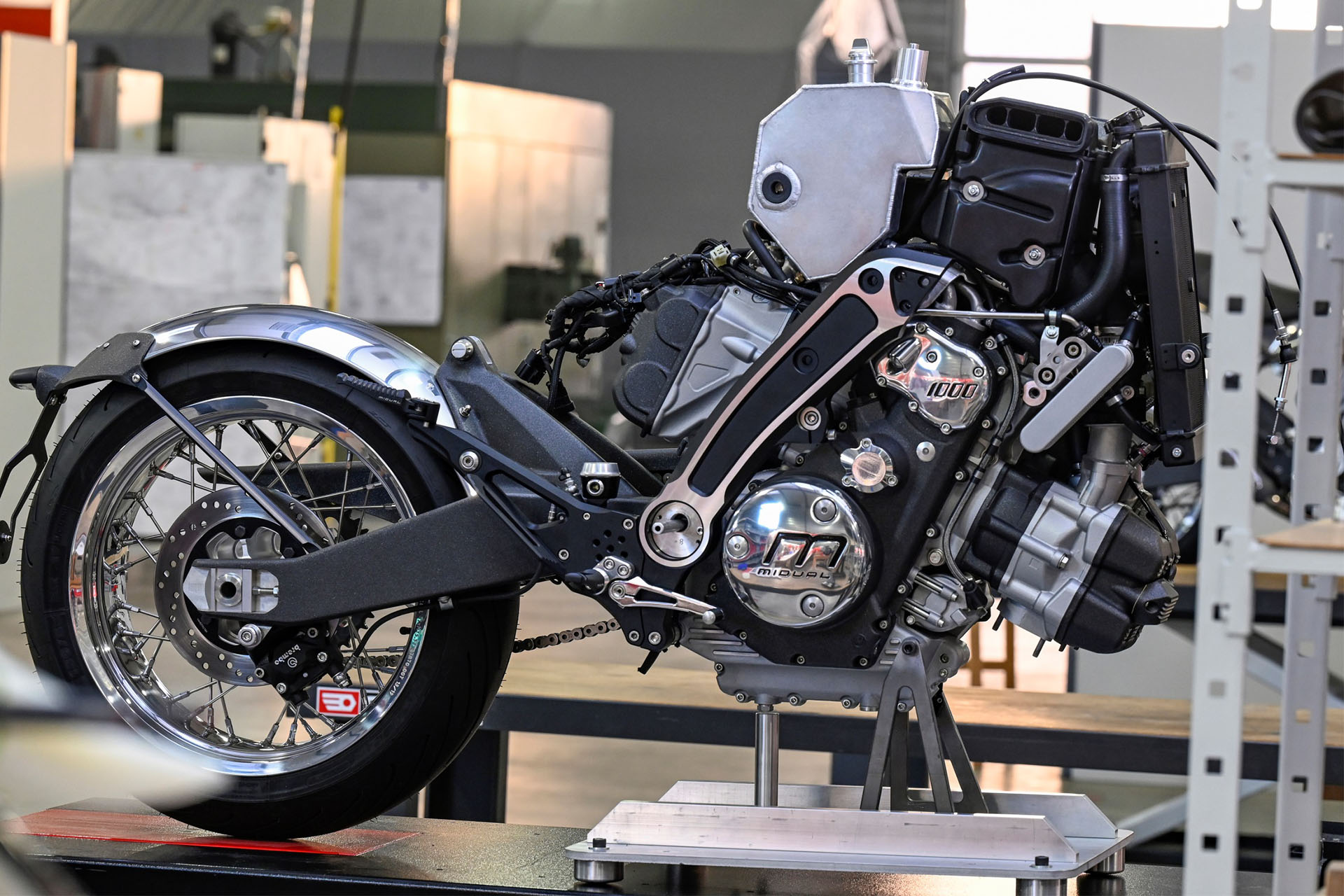

So the Midual is fitted with a fore-aft mounted flat twin, with a transverse crankshaft. To make this type of engine compatible with modern chassis geometry, the engine is tilted by 25°, with the front cylinder angled downwards. This results in a shorter engine, allowing a large radiator to be installed above the front cylinder, close to the wheel, while still leaving room for the front throttle body. The gearbox is under the rear cylinder, placing the output shaft in an ideal position for the construction of a long swinging arm, providing good road handling. This layout allows the crankshaft to be moved forward enough to increase the load on the front wheel (weight distribution 49% Fr 51% Rr). Everything is very narrow and allows for high angles of lean, and good aerodynamics. As for the engine geometry itself, the bore x stroke values are 100 x 66 mm.

- The exact displacement is 1036 cc.

- The engine is water-cooled.

- The crankshaft rotates in 2 plain bearings and 2 ball bearings.

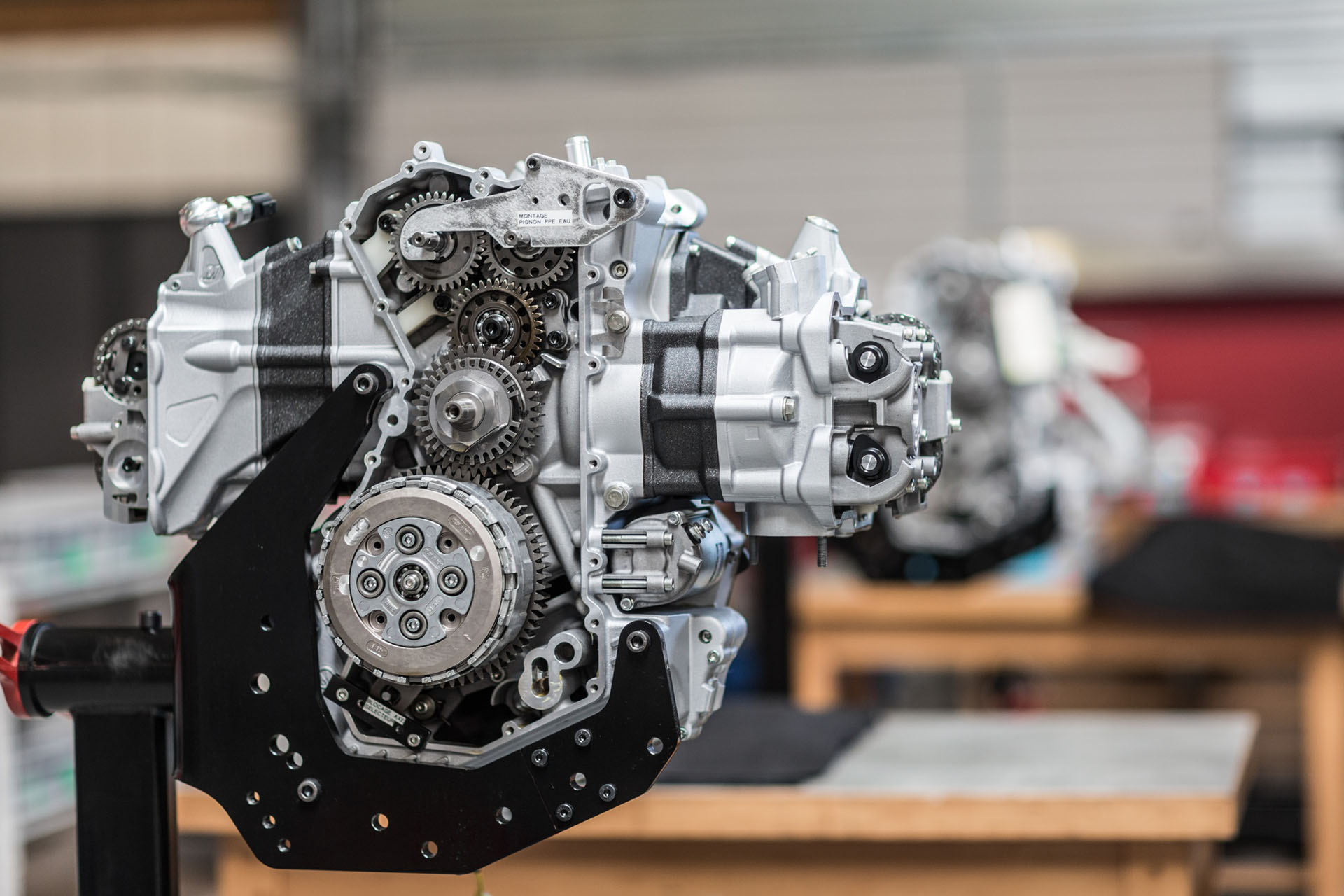

- The primary transmission has straight-cut gears with automatic mesh adjustment.

- The con-rods are machined from the solid and the pistons forged.

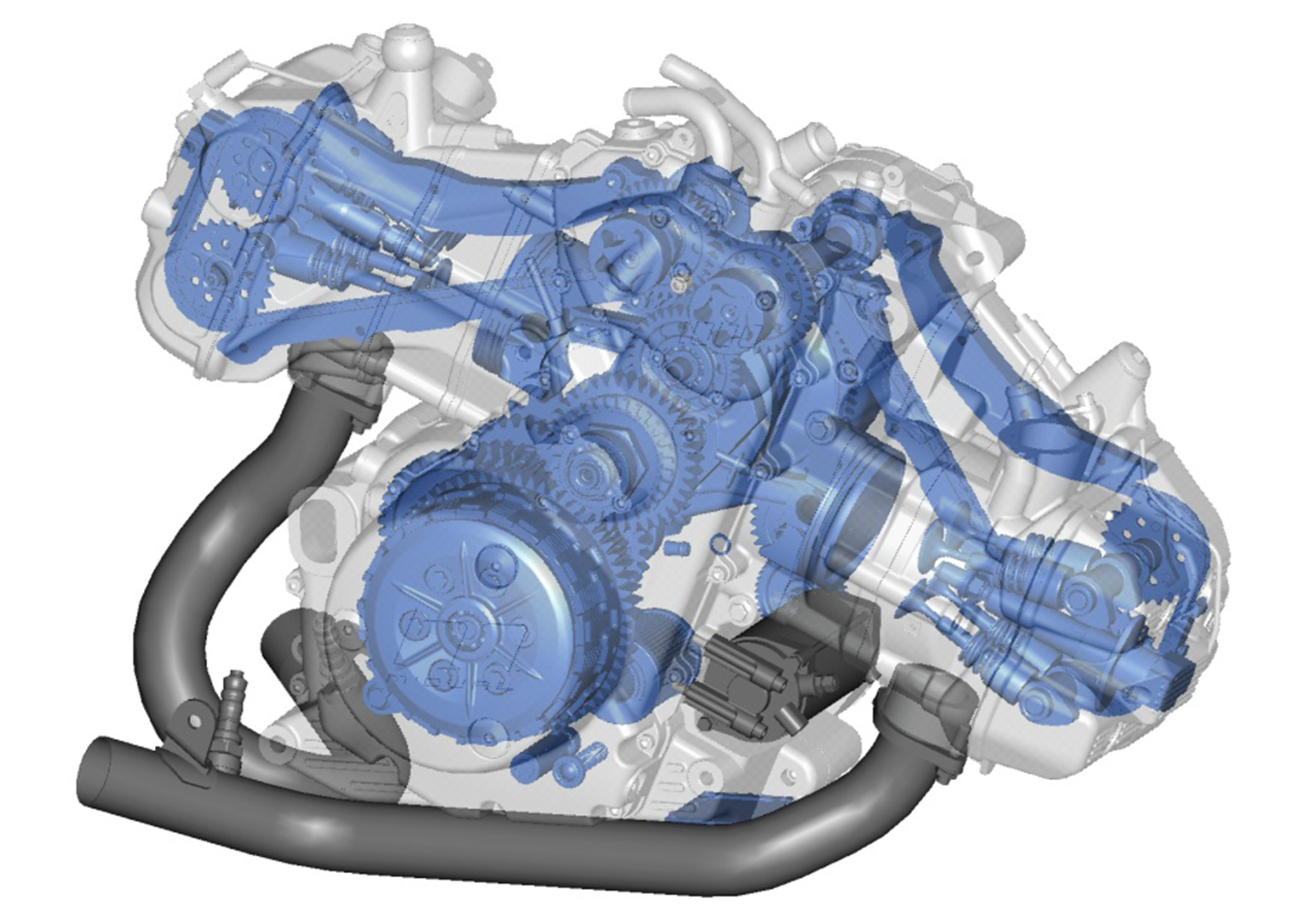

The timing gear uses a train of gears with automatic back-lash adjustment, driving 2 intermediate shafts, and then 2 short roller chains, tensioned by hydraulic tensioners.

The engine has 2 interchangeable cylinder heads, each with two camshafts, operating the valves via cylindrical tappets. The inlet valves are 36mm and the exhaust valves 31mm.

Lubrication is by a dry sump system, with 2 trochoid pumps, driven by the intermediate shafts. The front cylinder head has a trochoid return pump.

The water pump, also driven by one of the intermediate shafts, pumps water round the cylinders through drillings in the cylinder block.The vertical joint face crankcase contains a 6-speed gearbox and an anti-dribble clutch, driven by a straight-cut primary transmission with automatic clearance adjustment.

The air box is installed on the engine, as are the oil tank and the oil and water radiators.

Thus equipped with all its accessories and circuits, it constitutes a real power unit, and is tested as such in production.

The engine housings and cylinder heads are cast in a sand foundry in the Paris area. They are then entirely machined in-house, on 4 and 5-axis machining centres.